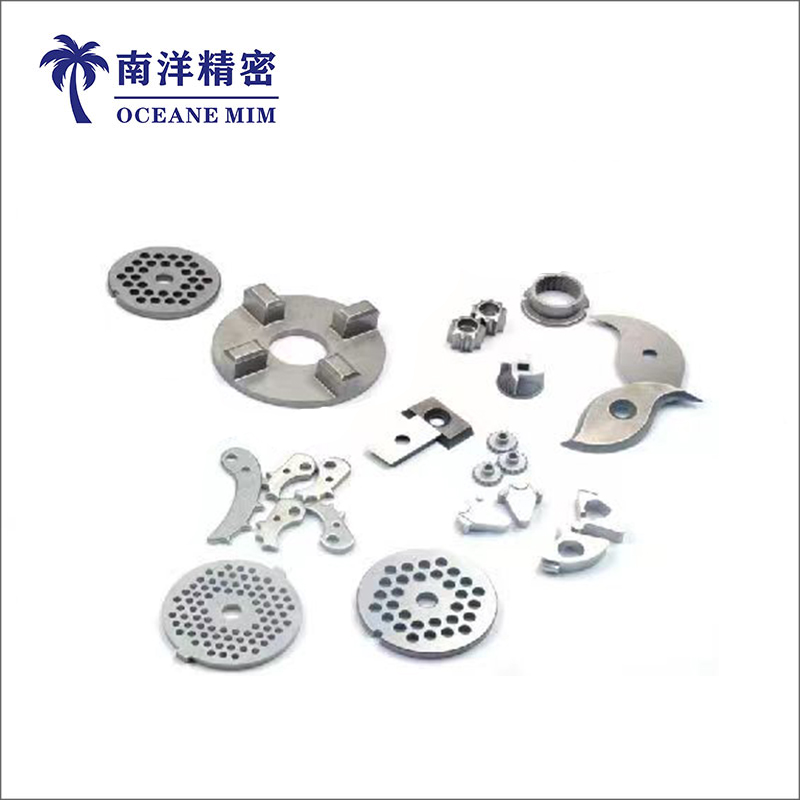

Various Sprocket Accessories in Pim Field

Various Sprocket Accessories in Pim Field is often necessary to optimize the design of the raw material powder (such as the selection of shape and particle size composition), and the metal powder compression molding process, through annealing or Diffusion annealing to improve powder plasticity, and high temperature lubricant (usually 0.6 wt%) is incorporated into the powder.

Send Inquiry

The main difference between the metal powder compression molding technology and the traditional molding process is that the powder and the mold are heated to a certain temperature during the pressing process, and the temperature is usually set within the range of 130~150 °C. The density of powder metallurgy parts is increased by 0.15-0.4g/cm3, and the relative density of powder compacts can reach 98-99%.

In this process, in order to give full play to the isothermal pressing densification mechanism of particle rearrangement and plastic deformation during the pressing process, it is often necessary to optimize the design of the raw material powder (such as the selection of shape and particle size composition), and the metal powder compression molding process, through annealing or Diffusion annealing to improve powder plasticity, and high temperature lubricant (usually 0.6 wt%) is incorporated into the powder.